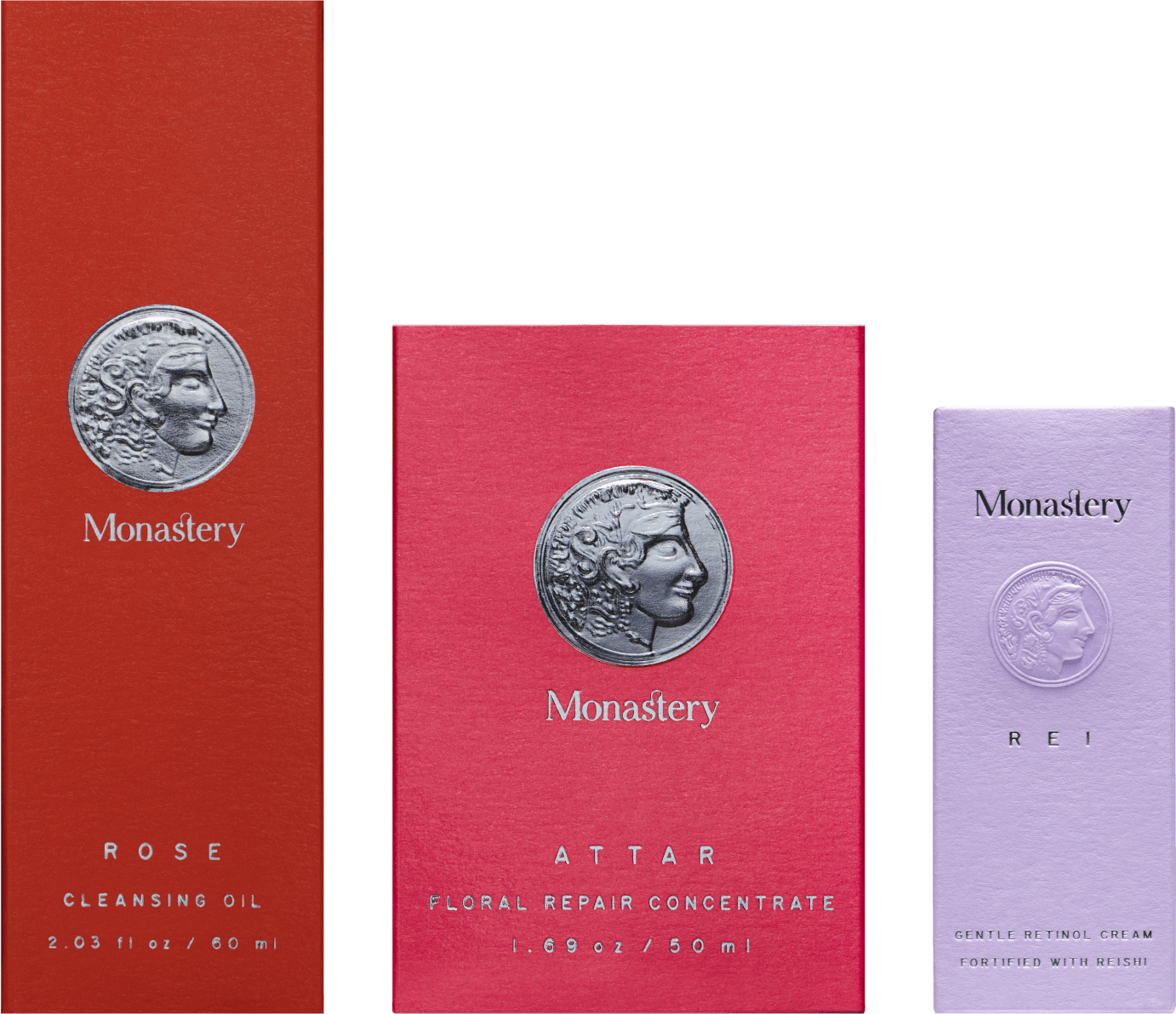

Spend a day in the lab making Attar, our cult favorite balm, with founder & formulator Athena.

Monastery operates out of our own lab headquartered in San Francisco, a rarity in the skincare business. There we formulate, produce and package every product that you see. Making everything in-house is at the heart of putting out the best possible product and remaining aligned to our mission of healing. What goes in the bottle is a true expression of our love and appreciation for the ingredients and their natural healing properties.

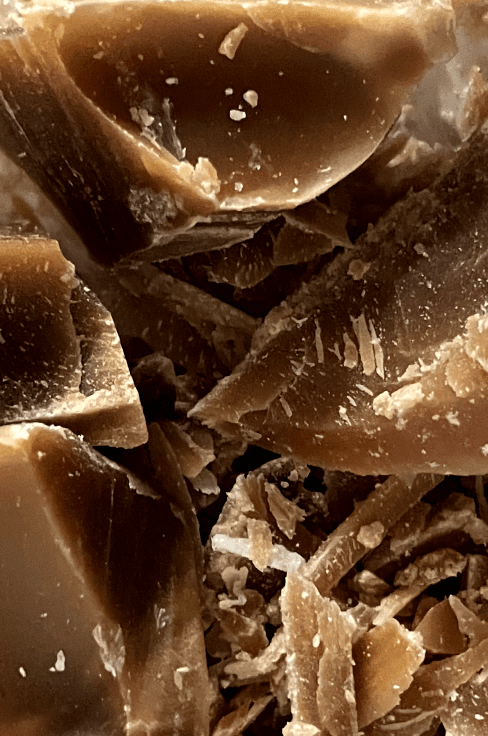

Once a year we get a very important shipment at Monastery. The shipment contains a special part of a flower. When we receive the floral ingredient it is too young to use because it came directly to us from the farm and it has to age just like a fine wine. This aging process takes 6 months. Once it is properly aged, it can only get better from there. Thankfully, this means that properly stored we can stockpile a lot of this ingredient.

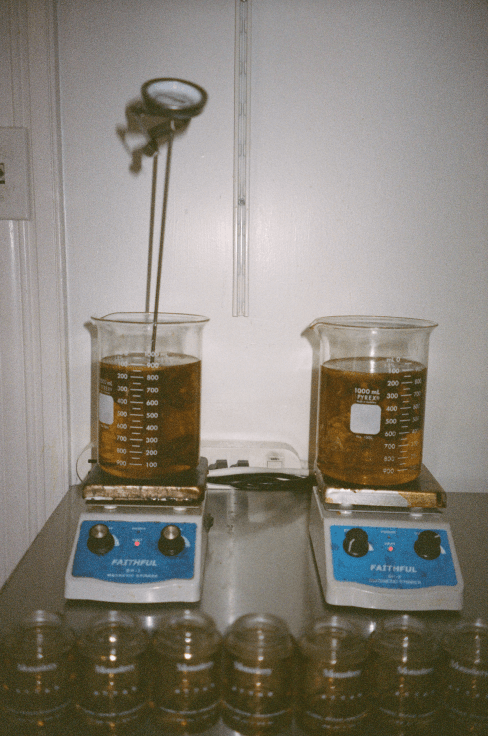

We make small batches of Attar in our manufacturing lab in San Francisco every Wednesday. Wednesdays are spent solely making Attar and in one day we can make a lot of it.

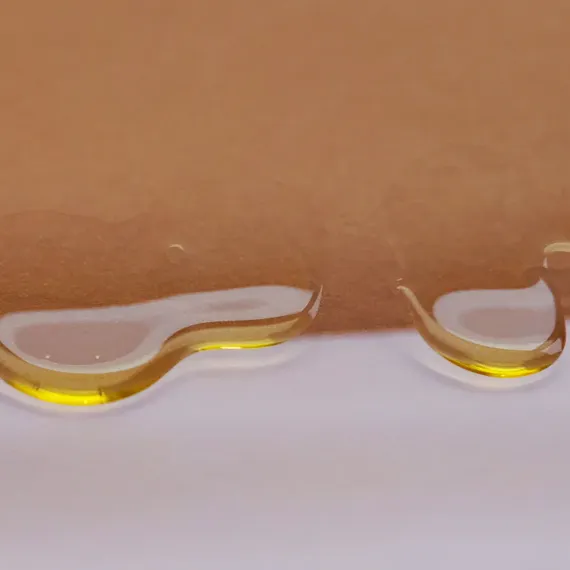

Temperature is key. The process of making Attar is a lot of healing and cooling. We are dealing with extremely precious ingredients so ensuring we’re not overheating is a delicate balance. We take each ingredient and place it into a large glass beaker. Each beaker is heated on a hot plate for a very specific time and at a very specific temperature. This ensures that the ingredients are perfectly mixed. This takes a few hours as we like to heat it slowly. With natural ingredients if they get too hot they can burn, just like when you cook any other organic thing on a stove. Heating slowly not only prevents burning but allows the ingredients to really shine.

Next up comes pouring Attar into our jars and tubes. When we hand pour the Attar we have to pour it at a very specific time within its cooling down period. The pouring has to be done rather slowly but not too slowly, you don't want the product drying in the jar while it's being poured but you also don't want to pour it when it's too hot either. Once the product has been precisely poured, we must wait 24 hours for the cooling period.

After the final drying is complete we check the Attar to make sure it looks great (a taste test) and then record this particular batch. From there we box it , stamp it with the best by date and prepare for it to head out the door – to our spa next door, to one of our amazing stockists or directly to our customers.

"I can’t imagine not being able to test every single batch that goes out to the door. Testing each batch gives me peace of mind that we are doing these precious ingredients justice." - Athena